|

Zhoushan Shenglong Machinery Co.,Ltd.

|

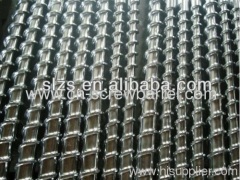

plastic proccessing blow film machinery single screw

| Price: | 100.0~10000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Commonly used material is 38CrMoAIA(nitrogen treatment),it can be changed as per your requirements. According to different usage

Specifications

single screw barrel for extruder

plastic proccessing blow film machinerysingle screw

it can be customized

plastic proccessing blow film machinerysingle screw

it can be customized

Diameter ofsingle screw :D15mm~D300mm

L/D: 12~45

Max.Length: less than10000mm

ScrewType:

Gradient-type,mutant, wave type, barrier type, dual type, shunt type, separate type, exhausttype, pin type, mixed type, double-headed type, three-type, long type, graintype.

Material

Commonly usedmaterial is 38CrMoAIA(nitrogen treatment),it can be changed as per yourrequirements. According to different usage, the choose for alloy is different,some require for abrasion-resistant while some require for corrosion-resistant.For standard, we have Fe-based, Ni-based, W2C alloy, Tungsten alloy etc forchoice

Materials& Processes

SKD61(H13) | 38CrMoAIA 41CrAMo7 |

Gr12MoV | HighQuality Duplex Stainless Steel |

42CrMo | HighQuality Powder Metallurgy Materials |

40Cr | Hard Metal Cold/Thermal Spraying Technology |

Zinc 3# Steel | Advanced Nitriding Technology |

Anti-corrosion and Wear-resisting Duplex Metal Spraying Technology | |

Screwstructure and compression ratio can be designed according to different products andmixtures

Technical Parameter

Nitrided CaseDepth | 0.5mm-0.8mm |

NitridedHardness | HV950-1020HV |

NitrideBrittleness | ≤GradeOne |

SurfaceRoughness | Ra0.4um |

ScrewStraightness | 0.015mm |

AlloyHardness | HRC58-62 |

Alloy Depth | 0.5mm-0.8mm |

Chromium Coating Thicknss | 0.025~0.10mm |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Plastic Blow Moulding Machinery

Plastic Blown Film Machinery

Machinery Screw

Blow Moulding Machinery

Extrusion Blow Machinery

Blow Mold Machinery

More>>